PLASTIC INJECTION MOLDING

‘We have multiple, ISO, IATF and AS certificated manufacturers who can help you manufacture your plastic injection molded parts on demand to the highest quality. We can provide small batch production or mass production services. We provide molding for wide variety of materials and for molding for up to 1000 Tons.

End to End Plastic Injection Molding Services

High volume manufacturing of plastic components suitable for identical product with tight tolerances.

HIGH VOLUME INJECTION MOLDING SERVICES

Your high volume plastic part requirements can be solved with DSPLTools to manufacture your plastic parts cost effectively.

High Volume Injection Molding Services

Your high volume plastic part requirements can be solved with DSPLTools to manufacture your plastic parts cost effectively.

Your high volume plastic part requirements can be solved with DSPLTools to manufacture your plastic parts cost effectively.

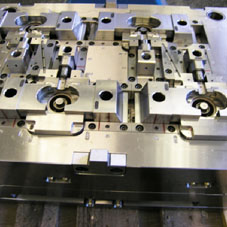

Your high volume plastic part requirements can be solved with DSPLTools to manufacture your plastic parts cost effectively. This process uses traditional hard molds that are made of steel alloys. The alloy selection greatly depends on the part geometry and the scale of production. We are also equipped with different injection molding machines with various tonnage categories from 1 Tonne to 1500 Tonnes making us capable of realizing both your micro injection molding and larger plastic injection part requirements.

PROTOTYPE INJECTION MOLDING SERVICES

Your product ideation, low production runs, validation and testing requirements can be fulfilled by our prototype injection molding.

Prototype Injection Molding Services

Your product ideation, low production runs, validation and testing requirements can be fulfilled by our prototype injection molding.

Your product ideation, low production runs, validation and testing requirements can be fulfilled by our prototype injection molding.

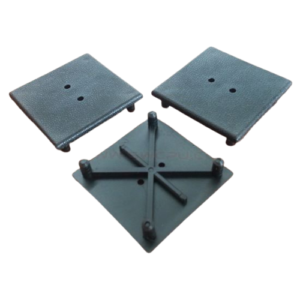

Your product ideation, low production runs, validation and testing requirements can be fulfilled by our prototype injection molding. We can manufacture your high complex parts using prototype molding. The mold is usually made of Aluminium, Epoxy, SLA, or urethane, based on the part geometry and the number of parts required.

ADDITIONAL CAPABILITIES

DSPLTools offers a complete injection molding services with the options of Insert molding, Over molding, Multi-cavity molding and family molding.

Additional Capabilities

DSPLTools offers a complete injection molding services with the options of Insert molding, Over molding, Multi-cavity molding and family molding.

Insert molding

When you need to include threads or taps to your plastic part, DSPLTools’s insert molding is the best choice for you. It can also be of use when you need to produce a wheel, pulley, or anything that requires plastic to be molded over a different material. This can be done for both prototype and full production runs.

Over molding

DSPLTools’s over molding solutions helps you combine two or more materials to make a single part. You can combine rubbers, silicones, plastics metals, and mold over the other to form a finished part. The only condition is that the first material must have a higher melting point than the second material. It has a wide range of applications, and it can be done for both prototype molding and full production runs.

Family molding

Family molding lets you manufacture different parts in a single mold, in a single cycle. It can help you to reduce your cycle time greatly. This method is ideal for prototype molds and for parts that do not require high precision, like toys. Our team of expert injection molding engineers can help you to make decisions on using family molding or in advising you on which components you should be going for family mold.

Multi-cavity molding

Multi-cavity molding lets you make more than one part per cycle and helps you save on lead time per batch. It can let you manufacture two, four or even eight parts per cycle. Our team of expert injection molding engineers can help you decide the most cost and time-efficient mold configuration for your part geometry and required capacity.

Why DSPLTools For Plastic Injection Molding Services

-

MULTIPLE INJECTION MOLDING FACILITIES

-

ONE STOP PLASTIC INJECTION MOLDING SHOP

-

UNLIMITED CAPACITY

-

CERTIFIED FACILITIES

-

TOLERANCES UPTO 5 MICRONS

-

COMPETITIVE AND PRICE MATCH GUARANTEE

-

PROPRIETARY SOFTWARE PLATFORM

-

MULTIPLE FINISHING OPTIONS

Finishing options in our Plastic Injection Molding Services

Glossy

Mold is made out of hardened tool steel, smoothed and polished with fine diamond powder suspended in oil, creating a mirror finish on the molded part. In SPI mold finishing standards, it is specified under A-1, A-2, and A-3.

Mold is made out of hardened tool steel, smoothed and polished with fine diamond powder suspended in oil, creating a mirror finish on the molded part. In SPI mold finishing standards, it is specified under A-1, A-2, and A-3.

Semi Glossy

Get a smooth glossy finish on the molded part. Mold is made of hardened tool steel, smoothened and polished with high grit sandpaper. In SPI mold finishing standards, it is specified in B-1, B-2, and B-3.

Get a smooth glossy finish on the molded part. Mold is made of hardened tool steel, smoothened and polished with high grit sandpaper. In SPI mold finishing standards, it is specified in B-1, B-2, and B-3.

Matte

The mold is finished by polishing with fine stone powder to create a matte finish on the molded part. In SPI mold finishing standards, it is specified in C-1, C-2, and C-3.

The mold is finished by polishing with fine stone powder to create a matte finish on the molded part. In SPI mold finishing standards, it is specified in C-1, C-2, and C-3.

Textured

The textured finish is obtained by pressure blasting of the mold with glass or beads. It creates a unidirectional textured finish on the molded part. In SPI mold finishing standards, it is specified in D-1, D-2, and D-3.

The textured finish is obtained by pressure blasting of the mold with glass or beads. It creates a unidirectional textured finish on the molded part. In SPI mold finishing standards, it is specified in D-1, D-2, and D-3.